Production

1. Sheets of steel and circles.

The birth of Dzen Drum begins with sheets of carbon steel weighing about 40 kilograms. We cut out blank circles on a laser machine - 32 pieces per sheet.

2. Molding into hemispheres.

After the laser, the circles are sent to a workshop with a hydraulic press. Here, using special equipment and under pressure mold, the circles are formed into hemispheres. Quality control of manufactured blank circles.

3. Petals.

The next step is to cut out the drum petals on the hemisphere using laser cutting. The laser operates according to a specific algorithm. Each Dzen Drum has its own drawing down to the millimeter. After this stage, you can already see clear lines of the petals.

4. Welding and cleaning.

Dzen Drum consists of two hemispheres, the upper one with petals, the lower one without (if we are dealing with a luminous Dzen Drum, the lower one has a hole in it). We weld them together and clean the seam so that the instrument has a perfectly smooth surface. Quality control is also present at this stage.

The birth of Dzen Drum begins with sheets of carbon steel weighing about 40 kilograms. We cut out blank circles on a laser machine - 32 pieces per sheet.

2. Molding into hemispheres.

After the laser, the circles are sent to a workshop with a hydraulic press. Here, using special equipment and under pressure mold, the circles are formed into hemispheres. Quality control of manufactured blank circles.

3. Petals.

The next step is to cut out the drum petals on the hemisphere using laser cutting. The laser operates according to a specific algorithm. Each Dzen Drum has its own drawing down to the millimeter. After this stage, you can already see clear lines of the petals.

4. Welding and cleaning.

Dzen Drum consists of two hemispheres, the upper one with petals, the lower one without (if we are dealing with a luminous Dzen Drum, the lower one has a hole in it). We weld them together and clean the seam so that the instrument has a perfectly smooth surface. Quality control is also present at this stage.

Stage 2

5. Sound and preparation for colouring.

At this stage, Dzen Drum is already making sounds, but the notes are false. Music requires precision, so our masters manually tune the instruments until the tuner shows absolutely pure notes tuned to a frequency of 432 Hz and 528 Hz. Then artistic engraving is applied, which adds charm and individuality to each instrument.

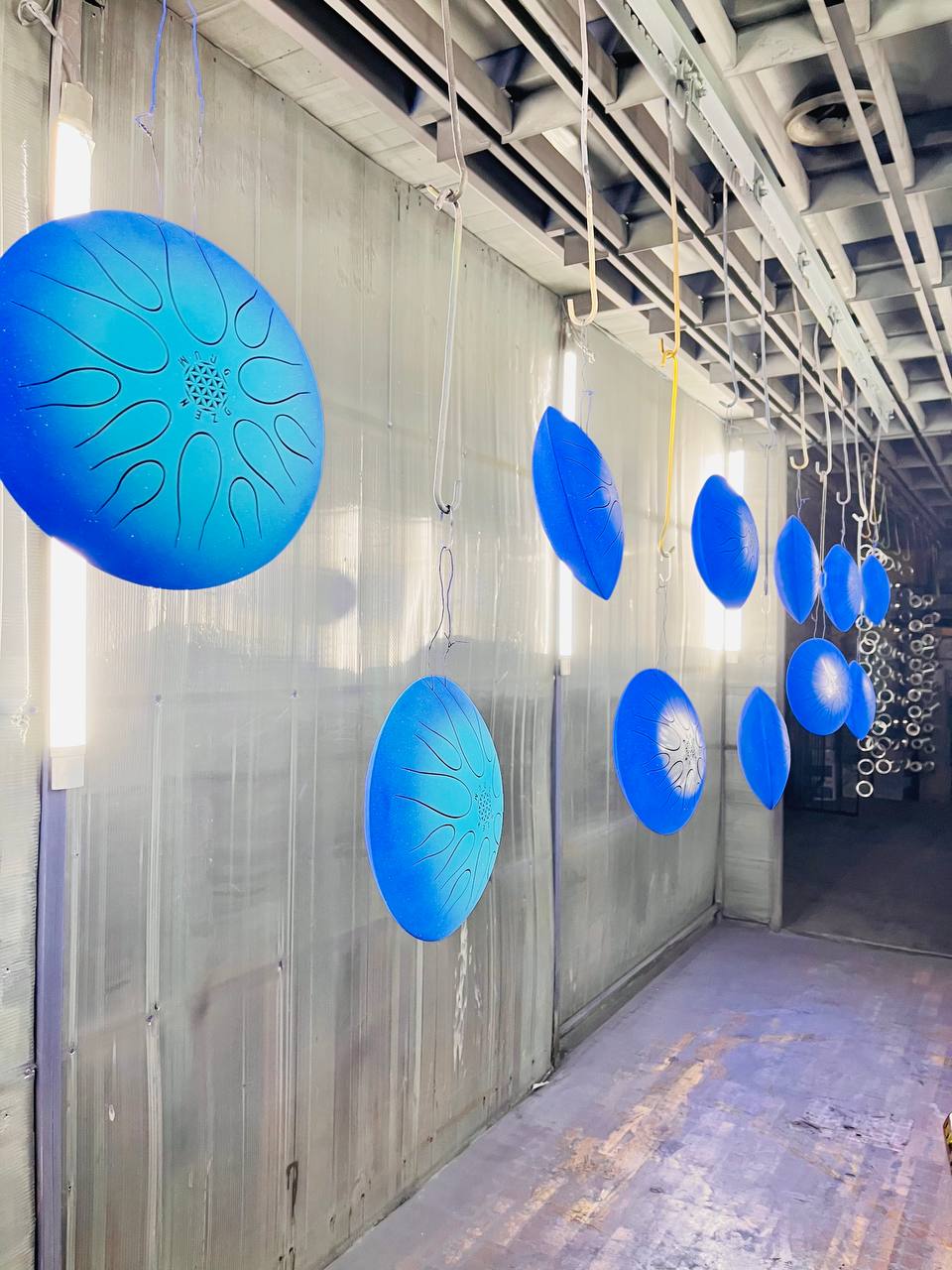

6. Hardening and colouring.

After the instrument has been tuned, we apply an anti-corrosion coating and send it to the workshop for colouring. We prepare the instrument for colouring: remove any remaining dust and degrease it to increase paint adhesion and additionally protect the product from corrosion. In the spraying chamber we apply powder varnish and send it to bake in the polymerization oven, under certain temperature and time so that a top coating forms.

7. Quality control and packaging.

Final check of the instrument according to the checklist: sound, quality of colouring, general appearance, etc. The final stage is when Dzen Drum is ready to ship.

At this stage, Dzen Drum is already making sounds, but the notes are false. Music requires precision, so our masters manually tune the instruments until the tuner shows absolutely pure notes tuned to a frequency of 432 Hz and 528 Hz. Then artistic engraving is applied, which adds charm and individuality to each instrument.

6. Hardening and colouring.

After the instrument has been tuned, we apply an anti-corrosion coating and send it to the workshop for colouring. We prepare the instrument for colouring: remove any remaining dust and degrease it to increase paint adhesion and additionally protect the product from corrosion. In the spraying chamber we apply powder varnish and send it to bake in the polymerization oven, under certain temperature and time so that a top coating forms.

7. Quality control and packaging.

Final check of the instrument according to the checklist: sound, quality of colouring, general appearance, etc. The final stage is when Dzen Drum is ready to ship.